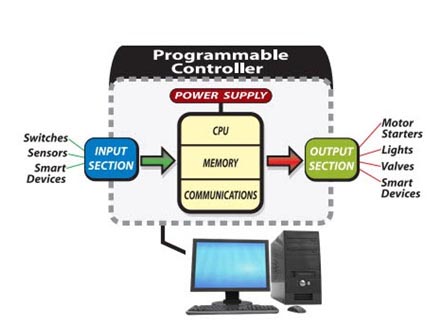

Ease in modification of logic, reduced size, means of remote communications and advances in the technology have made PLC based Control Panels an edge over conventional relay based systems. PLC of Allen Bradley, Siemens, Delta, Mitsubishi, LG. From small I/O application to the complex I/O systems are provided by the Control Systems Engineers.

Control Systems Engineers have developed communication software's for remote communication of the PLC Panels in various different protocols. With PLC based Panels HMI/MMI are provided to operator for various messages and controls of the process to effective control of the system.

Medival offer PLC Validation for companies in various industries after upgrading their existing systems with new PLC platforms/ any type of modification in PLC systems as well as periodic re-validation.

Validation protocol describes the scope, procedure, responsibilities and acceptance criteria for the validation. Validation protocols should comply with the respective SOPs.

Test data

Summary reports

E-Record generated reports(If available)

21 CFR compliance documents

Procedures

Certification forms produced during the validation process

Safety Features

Determine Validation strategies and Activities

Prepare the Validation Protocol

Perform validation activities as per approved protocols

Prepare validation report

Review Controls and Procedures

Certify the Documents (System)

MeDival Technologies staff are experienced in the validation of PLC systems, of various industrial facilities. Medival work closely with clients to develop quality validation protocols and reports. Our protocols include customized validation approaches and methodology with clearly defined, pre- determined acceptance criteria.

If you have any specific questions about us or any of our services, get incontact with us.